Topicality

By 2021-22, in the most important areas of the world, the goals of energetics, climate protection and the related instrument systems have been clearly formulated.

Thus, in America, the BCI and the CBI prepared the long-term energy policy roadmap based on the foundations laid by the DOE, and in Europe, in addition to taking into account the climate goals, based on the recommendations of EUROBAT, the EU also defined the goals to be achieved for the 30s and 2050 .

The key issue for both is energy storage, i.e. increasing the amount of emission-free energy (wind, sun) and storing it at the appropriate level and efficiency. (E.g. the goal is to establish a storage capacity of 200 GW by 2030 and 600 GW by 2050 in Europe) This is also reflected in the growth rate in terms of value:

source: Precedence Research

Both important roadmaps emphasize the imagined role of lead-acid batteries, and formulate specifics in this regard. It must be emphasized that it also sets development goals that cannot be met with the outdated structure and parameters of the currently manufactured LA batteries, but are integral parts of the realized innovations of the (existing) Blewin system.

They are like that:

• reduction of raw material consumption

• increasing the specific storage capacity

• "cleaning" the production process

The figure shows the current status of Blewin in terms of energy density of lead-acid batteries.

source: dr. Mészáros Tamás Uff Solution (2022)

But it is not only the specific energy density that makes the Blewin system stand out from the rest, as the material and energy savings are also exemplary, and the emission values of the lead vapor reduced to almost zero are exceptionally good. In addition, it shows "unusual" results in terms of its technical parameters, which increases its actual use value.

Two essential tools for achieving the climate goals are the use of the advantages of "sustainable development" and the "circular economy", of which the lead-acid battery can be an important element, since there is no shortage of lead, and lead is one of the highest percentage (95%) recyclable metals.

Blewin's role in this, lies in the fact that the production of such batteries radically limits the lead vapor emission of lead processing, and builds on principles and previously developed lead processing technology that can be the basis for further (relevant) developments.

Thus, for example, the Green Lead Project presented in 2021 can put the currently highly criticized recycling process on a new footing, radically reducing its energy demand and emission risks.

But there is still room for innovation in the process of lead processing, the Uff Solution published this year presents one of these steps.

The importance of lead-acid batteries has increased for high-performance ESS projects, because the Blewin batteries (also) suitable for this purpose make the initial investment value extremely favorable (30 ~ 35 USD/kw) compared to the currently "usual" and accepted by the market, but it is unrealistically high at 200 or more USD/kw.

Of course, this requires that the lifetime, quality and parameters of the batteries meet the current technical requirements.

Such systems are now in operation, e.g. the British Royal Mint and Exide's Portuguese plant have such storage capacity, but they use existing batteries that are not optimized for the purpose. It would be much more effective if the batteries used could be made specifically for this purpose.

The trend shows that the security of the energy supply, the expected efficiency of the systems, and the possibility of achieving the climatic goals continuously foresee the spread of high-capacity and efficient ESS systems, including the BESS (Battery Energy Storage System), within which there would certainly be a place for the Blewin for batteries!

A selected mathematical example of current waste, which is unfortunately true

The EU has decided to end the distributon of passenger cars equipped with internal combustion engines (petrol or diesel) in its territory in 2035.

According to today's statistics, this means 10 million vehicles per year, a total of 130 million vehicles. (the number is actually higher, as light commercial vehicles with a similar resource are not included in these statistics)

A starter battery is needed to start internal combuston engines, one is definitely present in every manufactured vehicle, but considering the 13 years, there will be replacements, so we can count on 180 million lead-acid batteries for this fleet of vehicles. (other system batteries are not suitable for this purpose)

To produce an average battery, it is necessary to process 12 kg of lead, so 180,000,000 x 12 = 2,160,000,000 kg, i.e. 2,160,000 metric tons of lead, will definitely be processed during the examined period. Namely, the 70+ year old, outdated and environmentally polluting way of manufacturing lead-acid batteries, under rather wasteful economic conditions.

Batteries produced in this way have a high specific lead requirement, a low specific power (~60 Wh/kg), a limited lifespan, but are stll marketable, because there is nothing better - currently - on the market.

However, it exists!

An LA battery complex production system capable of a specific power of 80 Wh/kg is, for example, the developed Blewin system, but with further improvement of the building elements, a specific power of over 100 Wh/kg can also be achieved.

It is worth considering what change results from the use of a battery system with better technical parameters (with the use of this amount of lead):

- Compared to the current specific value of 60 Wh/kg, the value of 80 is a 30% increase in performance, which means that the mass of each manufactured battery can be reduced by 30%, so 3 kg of lead worths 7 USD at the market price can be saved per battery.

- If saving is the only goal, the level of environmental pollution can be reduced by this amount, and the recycling process, which is currently highly criticized, is also simplified.

- As a better solution - since it would have been manufactured anyway - it can be used for other purposes (e.g. as components of energy storage blocks of any power). In other words, 540 million kg (540,000 tons!!!) of manufactured lead is available - provided that the production technology makes it suitable for use for other purposes.

If so, a storage capacity of 43 ~ 43.5 thousand Mwh can be built from this amount. Its value (built from LA batteries) exceeds USD 1 billion at daily prices, and from batteries of other systems (e.g. Li-ion) it is more than USD 4 billion.

In solving the European energy crisis, the investigation and reevaluation of realistic alternatives, the aspects of logical resource allocation and reasonable material management, and the unjustified shift towards non-recyclable materials and technologies simply cannot be ignored. This is especially true if we have ready-made complex solutions.

A new solution in lead-acid battery technology

CBI Request for Proposals (RFP) 2022

In 2018, this system was introduced at the Hannover Battery Expo to the public for the first time; at that time everything was about and everybody was fascinated by alkaline (Li) batteries – however, this has been the situation ever since – but the few years that have passed have shown that LA batteries still have a considerable role (and market) in the field of energy storage.

The problem is that new, modern and better variants would be needed instead of the average versions mass-produced at present using a technology aged 70+. Moreover, the production (and recycling) of these batteries today is criticisable from an environmental aspect, however, the (elaborate) recycling of lead is an aspect of high importance.

The level of innovation in this field is minimal, and if any, it does not bring any significant changes. At the same time large companies (Excide, GS Yuasa, Hoppecke) use the ‘classic’ construction principle (for Ess solutions and using pure lead grids), and the ‘bipolar’ layout is spreading, but the specific power is still low. The improvement of this is economically reasonable as the market demand explains this due to the rather favourable initial investment value of lead-acid batteries.

Likewise, it is of high importance that lead-processing should be clean and safe.

Blewin battery system fulfils the following important criteria:

- Makes the critical technology of lead processing clean (emission free)

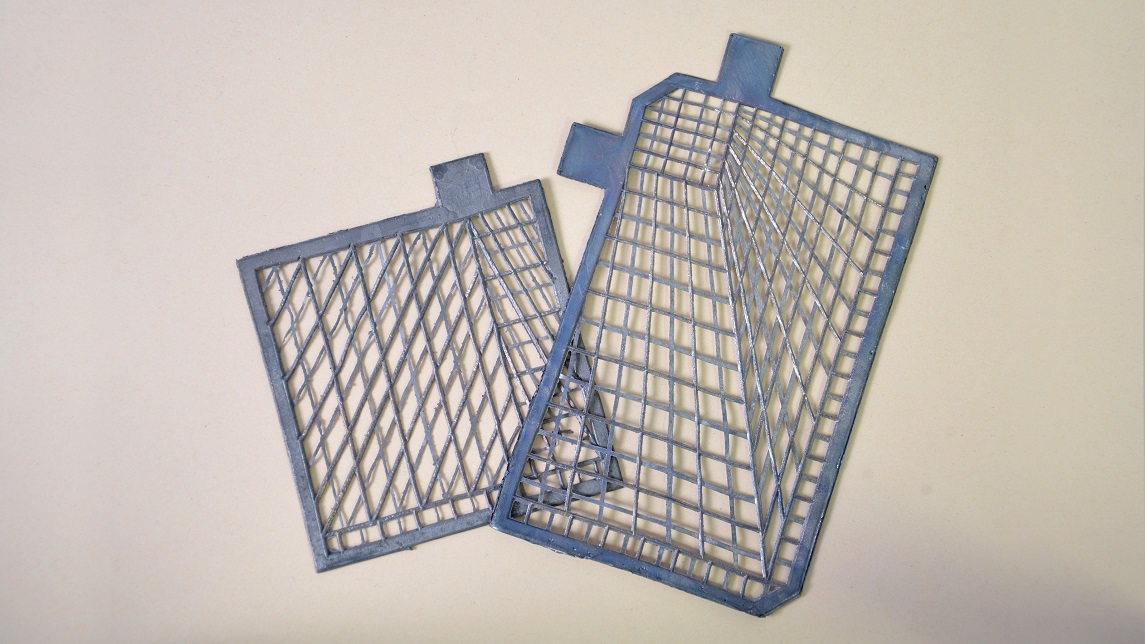

- With a new technology allows for the large-scale production of lead grids better than ever. This is necessary to provide a new dimension for any further technological and qualitative parameters

- A good battery can only be constructed from good construction elements (grids), that is the relevant grids are made from pure lead with radically reduced internal resistance, based on the grid geometry optimized for the current paths.

- The surface with high electro-chemical activity is outstandingly large, the current density can be of an extra value (during charging and discharging as well).

- The mass of the grids of those manufactured by classic casting or expansion, the savings in material (an energy) is provably considerable, and the final result (based on tests) is a specific power of ~80 Wh/kg occur accompanied by other favourable properties.

- Modular, cell-built, it can be repaired by replacement of the cells, however its service life is longer than usual due to the pure lead grids. At the same time repairs are unlimited.

- It is equally suitable for e-motion drives, for the establishment of emergency and auxiliary power supply, for the power storage of solar panels and low-power wind turbines, and highpower mains requiring ESS as well. During the development the use in fields where energy storage is not yet available was taken into consideration, and where technically unreasonable and expensive solutions are used due to constraints.

- It is outstandingly cost-effective, due to its low initial investment demand and extremely high recycling rate (~95%) of lead it can become a foundation pier of decarbonisation. At the present price level, the specific investment value of energy storage systems built up of Blewin system elements – related to storage capacity – is about $25/kWh.

There are several connection points in the list of issues to be acted upon which are – partly or fully – solved by the Blewin system, but these possible solutions are not utilized as necessary. At the same time, some ‘irregular’ technical improvements reasonable from an environmental an economical aspect are related, which carry on with the Blewin ideas, as these improvement lines have got some ‘reserves’ to be (or which could be) utilized.

Please, find a list below thematically where the Blewin system solutions can be utilized in the future (www.blewin.li):

1.

4. Understanding and improving high-rate performance without associated - capacity reduction.

a. Alloys and active material studies to enable thinner plates

b. Acid concentration effects and impacts on diffusion

All the quality parameters of lead-acid batteries built up in the classical way depend on the grids. On the one hand, the material of the grids is determining, on the other hand, the geometrics of the grids are essential. These two factors depend on each other in a way that the grid manufacturing technologies used today actually set out the material composition of the grid, which is not in all cases optimal. The same applies to grid geometry. The geometry of the large-scale produce (expanded) grids is doubtful and far from the optimum. (This is primarily true for batteries used in the motor vehicle sector.) This order of more than 70 years also affects grid mass as it is unreasonably high, and the presence of Ca is specifically damaging due to gypsification (CaSO4). Mass retention and the porosity of the grid surface are also criticisable. Rigid grids are sensible to vibration, which also limits their service life.

The Blewin system introduced a new grid production technology, the objective of which was to terminate known deficiencies, and a significant reduction of environmental pollution by the criticisable lead processing. So, a clean grid production technology suitable for large-scale production is available, which is suitable for producing grids of lead with optional composition and optional grid geometry for constructing batteries. In possession of the above information it is also suitable for improving important technical indicators as the optimized fibre conduction considerably reduced internal resistance, the electrochemically active surface was increased by more than 60%, and the fibre layout and microporous surface provided for the outstanding mass retention, and since pure lead is used, sensibility to resonance is terminated. As a final result, instead of the 65-85 g grids used today the same capacity can be provided for by 36-42 g grids. Tests have proved that batteries built up of such grids are capable of a specific power of 80 Wh/kg, which ‘translated’ to common language means that with a 2.6-4.0 kg reduction of weight in case of a starter battery (approx. 7 $/pcs) lead can be saved (and with the same power).

During testing of batteries built of such grids the independent university laboratory measured (and documented) further considerable results:

- Significantly higher charging current (current density) can be used without any damages,

- Significantly reduced charging time

- There is no heating or acid fume emission during charging

- Secure operation even charging and discharging on -18°C, it is less sensitive to cold. This is due to the outstandingly high electron activity.

Those written above show that the proper production engineering is enough to produce considerably better grids than those of today in both material and layout.

The Blewin system provides for the large-scale conditions for this by the process applied. The results are rather stringent, although 80 Wh/kg is not bad for a first step, yet it can be further improved.

The ‘Uff Solution’ describes the mathematical model of the grids produced on a large-scale necessary for reaching a specific power of about 100 Wh/kg. (https://www.youtube.com/watch? v=KnbsN58YBJc) At the same time, Uff2 is on its way, which may bring a further 10% increase in power with another grid geometry reconstruction. (In this case ‘Uff’ is not an Indian battle-cry but the abbreviation of the fibre method called ‘Ultra fine fibre’) Today’s industrial processing systems allow for this.

As in case of the Blewin system, the quantitative ratios of classical reaction equations must be looked to in an increased way in these cases so that the quantitative ratios of the reactants (lead, lead oxide, electrolyte) are right, otherwise the efficiency can considerably deteriorate (as in case of e.g. ‘acid-poor’ AGM batteries).

The use of any other additives should be avoided which are not indicated by the reaction equations, this is also relevant to neutral nanostructures as well, as these can bereave one of the most attractive properties of lead-acid batteries, that is the capability of using high current

2.

... Additives and electrode material enhancements for improvements in operational life and total energy throughput

The KPIs that are most important to focus on are operational and acquisitional cost – cycle life and energy density improvements will assist with cost.

Although the use of pure lead grids (electrodes) is not new in battery industry, it is not wide-spread or used on a large-scale as it is rather difficult to produce usable grids made of pure lead. During the Blewin improvement using grid production technology (also) capable of the above and the improvement had a key role. The model was available as it had already won the silver medal of the Geneva Innovation World Expo in 1996, but the large-scale production method has become outstandingly environment friendly, energy saving and economical with this improvement.

As the effectiveness of the classical construction method (has been and still) is criticisable from several aspects the objective was to utilize the inherent reserves as ~30% of increase in efficiency was achieved besides some other favourable properties.

Referring primarily to these it is recommended to actually utilize the – at present hidden – reserves in the future, and to realize further related improvements.

The basic concept made the production of four types of batteries available:

- Electric bicycle, moped, and emergency power supply

- Classic (DIN-series) starter battery and half of it – for special purposes. This is the management of energy peaks of shunt circuits in certain vehicles (start-stop system power supply, and extra-low voltage (60 V) ‘mild hybrid’ drive). Such a battery with a small weight (7-10 kg), small volume (~2.5 l), with very low internal resistance, but with an extra large electro-chemical surface, and with an internal structure (and characteristics) especially adjusted to the reliable management of high current is still missing from the range of manufacturers therefore, solutions are poor, compromise, or rather expensive, or these are such experimental developments which try to provide for the solution with extra additives (graphite derivatives). This should be avoided as they impair the circular adjustment of ‘classic-built’ LA batteries into the economy, therefore making the returns doubtful. Generally

- Version improved for ‘domestic’ solar panel system power storage or for e-mobility purposes differing from the prior only in the internal layout (number of grids).

The tendency of that time – exactly due to the lack of good grids – started in new ways, splitting from the traditional construction principles, and at the same time with the most valuable properties of the classic LA batteries (managing high current, and simple recycling). … and batteries of different structures have emerged, the improvement of LA stopped, technology of 70+ years are seen everywhere.

We connect to this aspect as measurements and our experiments have proved that the last version is capable of serving an ESS system of optional size (capacity), that is it is capable of storing an optional amount of electricity (from any source) by simply changing the number of cells.

Some general characteristics of the cells are:

- Depending on the expected characteristics, it includes 14-17 grids of pure lead with special intermediate insulators, greased with ‘common’ mass, made tight

- It is lower than usual as the segmentation effect of the electrolyte is faded this way. Besides, it can be built in under the floor in vehicles with low floor-level, if needed. (Would be needed but nobody uses it…)

- Can be arranged in groups of 6 or 12, making up for a rack (with external connections), connected to the bars, built in a separate case. This way the double-wall vessel provides for safety in case of any damages, any unexpected failure can be prevented by replacing the rack, or any discharged rack can be replaced by a charged one; individual cells within the rack can be replaced in case of failure, making the service life actually unlimited as there is no heating or electrolyte fuming either. It does not include any unnecessary elements; therefore, the classic electro-chemical processes are not disturbed by anything…

- A speciality worth mentioning is that it can be recycled in a closed system in a way that only the cell cover and the intermediate insulation are recycled (processed) plastic (the rest only needs cleaning!), the lead and lead oxide can be reformed into new grids using a method with minimum loss and without any harm to the environment (e.g. Green Lead Project (https://www.youtube.com/watch?v=r8u_xxQWblY&t=8s)), only the electrolyte is neutralized (wasted). It is hard to find any other recycling process with such efficiency

The use of batteries with this system can have the following technical and economic advantages:

- Primarily, the outstandingly low initial investment value (~ 25 $/kWh) is rather important, accompanied by

- Low operational costs (favourable LCOE value)

- Its lifespan is actually unlimited, but due to the extremely economical recycling such control or overhaul (replacement) cycles can be established for operational reliability, which ‘follow’ the life cycle of the producing source (solar or wind power station)

- Specific power of 80 Wh/kg, and 160 ~200 Wh/l are outstanding values, whether it is used in an energy storage system of any capacity

- The environmental damage caused by the sustainable production – operation – recycling process extremely effective from the aspect of the circular economy is minimal, provided by existing technology steps and tools.

- Recycling rate of lead has an extremely high value in case of using the poor (and expensive) technological processes used today (~ 95%), but it can considerably be made more economical and cleaner as a return by the special grid construction technology.

- The improvements recommended can be ‘expanded’ by further two steps resulting in even better grids and batteries. Of course, this is all within reasonable economic limits and by maintaining previously achieved environmental improvements. This does not involve increase of the initial investment costs. Related technical know-how is also available.

- The grid production technology developed for the Blewin system can be integrated into the technological process of all LA battery manufacturers by a minimum modification of some elements, replacing the present obsolete, uneconomical, raw material-wasting methods, improving the quality of all makes, and eliminating present harmful effects (danger of sulphating).

- The application of the recommended technologies can result in such a complex technicaleconomical solution which can dissolve the present, righteous complaints against lead, and can terminate ‘frequent’ environment protection penalties, and making lead-acid batteries an inevitable, economical and safe element of energetic solutions of a sustainable and circular economy, based on their quality and specific performance indicators.

All processes included in the proposal (Blewin, Green Lead Project, Uff Solution, Uff2 ) constitute an individual, protected intellectual property, please, handle them as such.

Budapest, 03. 05. 2020

dr. Mészáros Tamás