Producing Technology

Thanks to new production technology is thinner, korrens grids can be produced, the now usual 65 - 90 grams/pieces, electrical aspects only limited relevant grids of 30-50 grams, for electrical aspects (Ohm's and Kirchhoff's laws) optimized, is less susceptible to corrosion and sulfation grids may be replaced.

Due to the thinness of the number of pairs per cell mounted grid is increased, thus increasing the value electrochemically surface.

But with this technology can be manufactured for operating in battery factories any shape and size grids, the difference is that this technology is the current cost per tonne of lead grid array converting less than in half, and share of energy demand is much less, which makes it really good for environmental pressure.

In addition, not cause lead-vapor emissions, which unfortunately is inherent is in the currently most widely used lead-grid manufacturing process.

The processing technology allows arbitrary material such as pure (99.9%) of the formulated free from lead alloys chosen as desired.

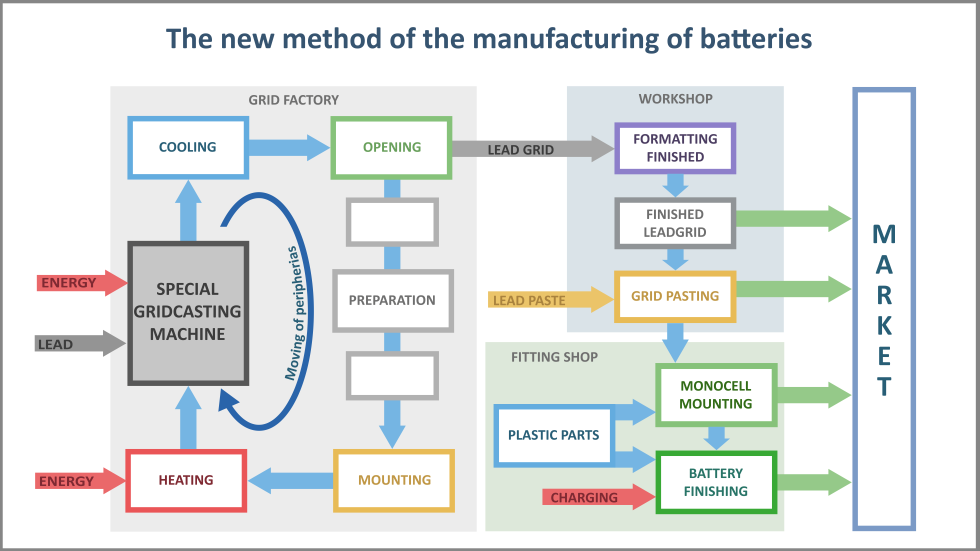

The grid manufacturing and battery assembly separable, ordering the grid production to lead production process, the assembly to use and sale.

The process